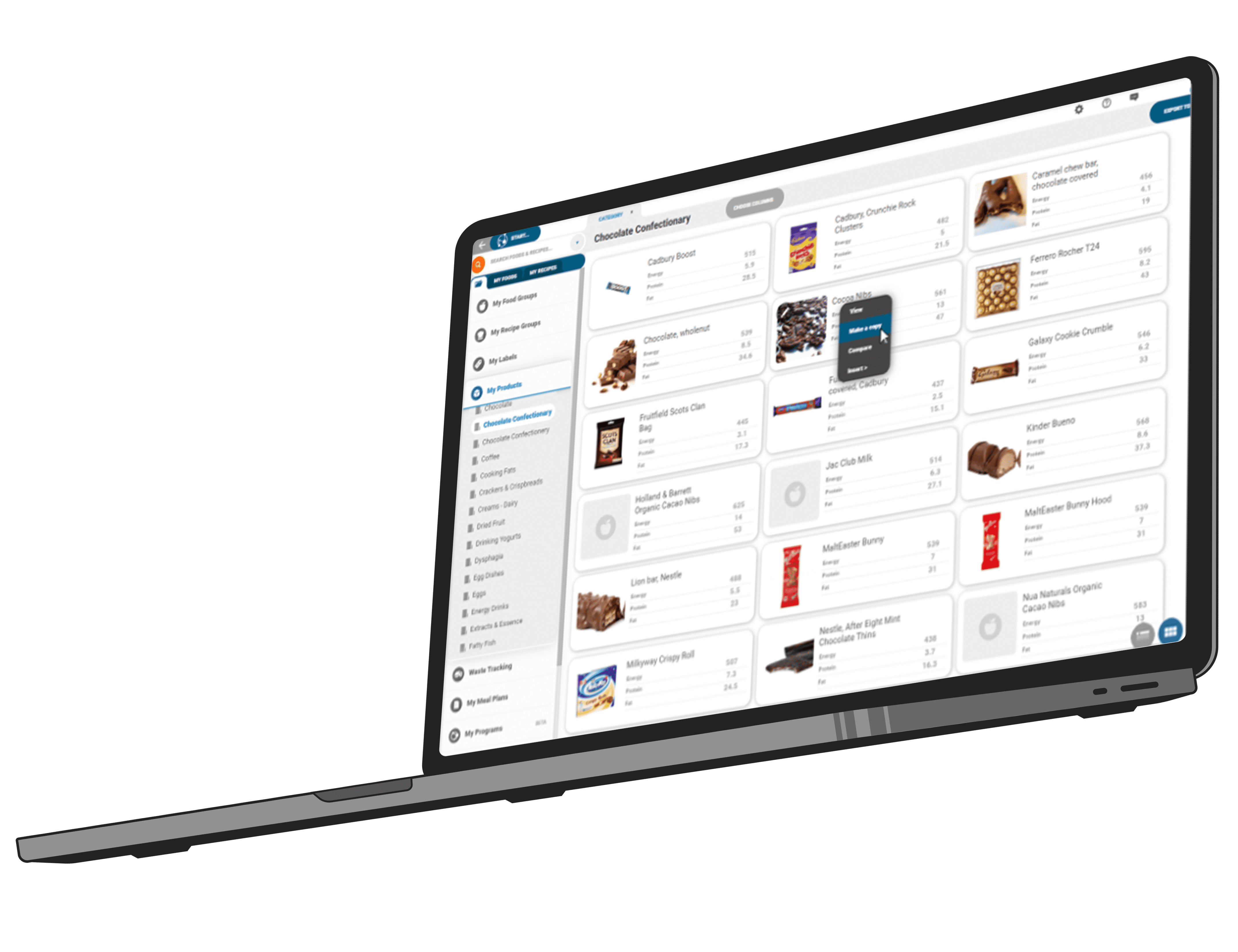

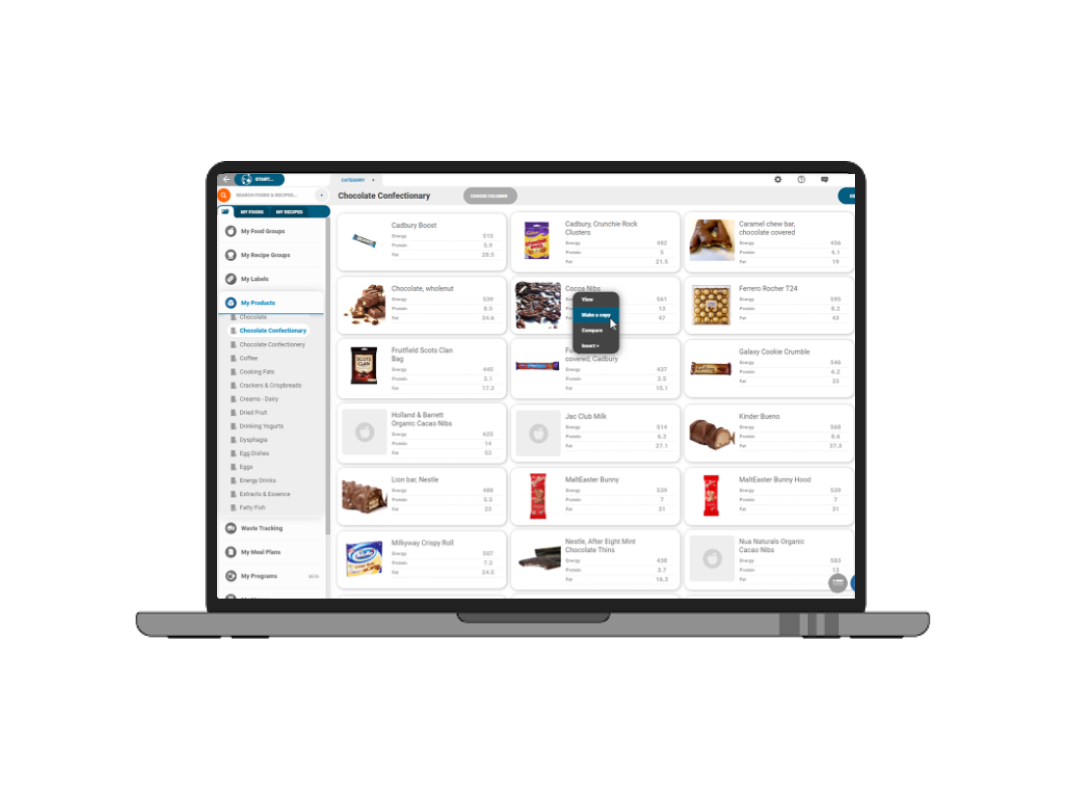

- Drastically Reduces Manual Entry: Eliminates the time-consuming and tedious task of typing product information line by line.

- Minimises Human Error: Reduces the risk of costly mistakes and typos that occur during manual data input.

- Accelerates Onboarding: Allows you to add new products to your portfolio in a fraction of the time.

Surefood

Save Time, Build Trust, and Control Your Food Data.

Distributing supplier data can be a time-consuming and manual process. That’s why we built SureFood, an intelligent new platform designed to solve the daily challenges of managing food information.

SureFood transforms the complex process of data management by using powerful AI-powered automations to centralise, validate, and share your product data across the entire supply chain. It saves you valuable time, eliminates tedious manual work, and ensures everyone has access to the same high quality, trusted information from a single source.

AI-Powered Data Import

Batch Publishing & Notifications

- Maximises Efficiency: Saves significant time by removing the need to update products and inform customers one by one.

- Ensures Instant Synchronisation: Guarantees that all partners are working from the most current data at the same time, eliminating version confusion.

- Improves Partner Communication: Demonstrates professionalism and proactivity by keeping your supply chain informed automatically.

- Streamlines Your Workflow: Simplifies the entire process of managing and communicating product updates.

Enriched Supplier Profiles

- Showcases Your Brand Professionally: Presents a complete and trusted view of your business, going beyond simple product specs.

- Centralises Key Documents: Acts as a single hub for all compliance and quality documentation, making it easy for partners to find what they need.

- Builds Trust and Credibility: A well-maintained profile with up-to-date certifications enhances your brand’s reputation for quality and transparency.

- Reduces Audit-Related Stress: Keeps all necessary documentation organised and easily accessible.

Instant Sharing Portal

- Dramatically Reduces Admin Requests: Frees your team from constantly responding to individual emails and calls for spec sheets or data.

- Empowers Your Partners: Gives customers and internal teams 24/7 access to the information they need, when they need it.

- You Control the Narrative: Ensures everyone sees the same, correct, and up to date information directly from the source.

- Enhances Professionalism: Provides a modern and efficient way to share data that reflects well on your business.

Your dedicated API

- Creates a Single Source of Truth: Guarantees absolute data consistency across all your platforms (e.g. ERP, e-commerce, internal systems).

- Eliminates Repetitive Data Entry: Automatically syncs information, removing the need to enter the same data into multiple systems.

- Prevents Versioning Errors: Ensures that any update made in SureFood is instantly reflected everywhere, eliminating the risk of using outdated information.

- Future-Proofs Your Data Management: Provides a scalable and robust solution for building an integrated, automated data ecosystem.

Real-time, science-backed

and seamless.

Seamless data, from farm to fork

Dealing with supplier data can be a time consuming and manual process. That’s why we built SureFood, an intelligent new platform designed to solve the daily challenges of managing food information. SureFood transforms the complex process of data management by using powerful automations to centralise, validate, and share your product data across the entire supply chain.

Frequently Asked Questions

How do I get my products into the system?

The simplest way is AI-driven batch import. Upload a product list or a folder of PDF spec sheets and our AI will parse and import it – ready for your review.

Additionally, we provide your suppliers with an account to our Supplier Portal, then we give you access to re-sell or build recipes with this data.

Can I re-use the product data after SureFood has cleaned and validated it?

What makes your supplier portal different from others?

A lot of systems give free rein to suppliers to upload whatever they want, without interrogating the data they upload. Nutritics is different in how we make sure that the information is correct and safe. Through machine learning, AI and big data we quality assure the data they upload to protect you and your customers from harm, by rejecting any information we flag as incorrect or needing review.

Where do you get the data from?

Nutritics holds one of the largest food databases in the world (1.6 million products and growing) that you are welcome to use, but we would recommend using data provided directly by suppliers. This means that you as the operator do not need to manipulate or make changes to the data, as it is an exact match to what you purchase.

What happens when products change?

You will be notified within your Nutritics account if one of your suppliers makes any product change etc, so that you can be sure you are always using accurate up to date information. Similarly when you make a change, your customers on the Nutritics platform are notified and prompted to update their records.